1774 Courses in Belfast

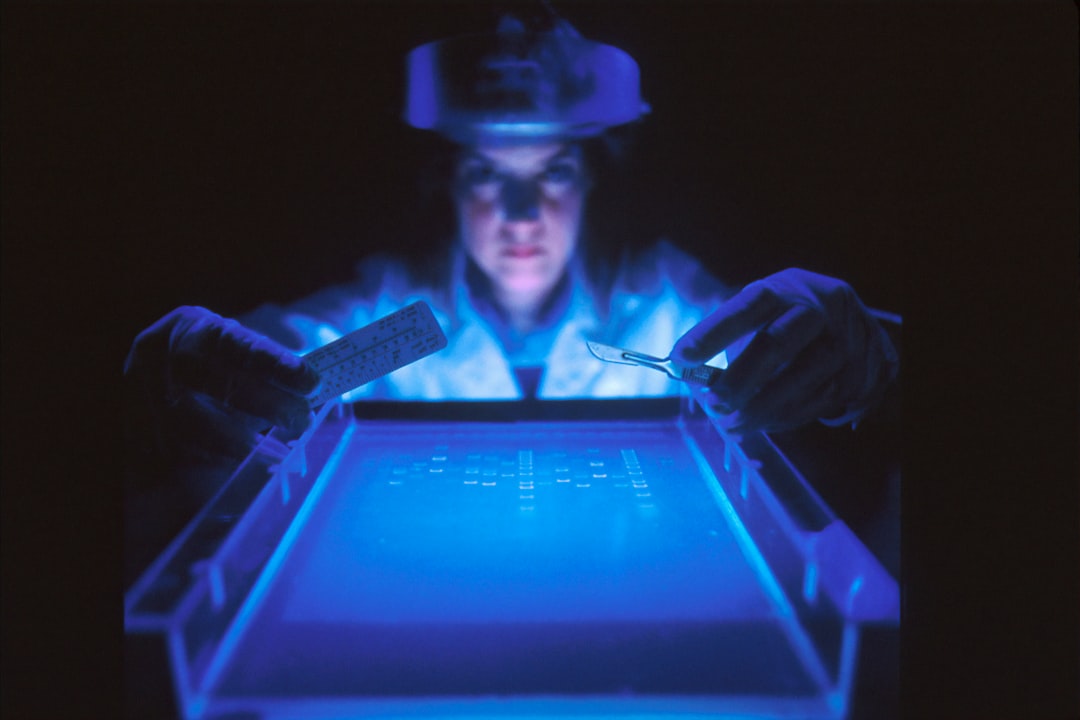

The Nebosh General Certificate gives individuals the skills and know-how to complete their health & safety responsibilities within their working environment. It can also be used as a first step in a career within Health & Safety.

The NEBOSH National Diploma is designed to provide the underpinning knowledge for a professional career in health and safety. The course is suitable for both newly appointed safety practitioners and those with substantial experience who wish to obtain Chartered Membership of IOSH. It equips holders to advise on effective management of risk across the range of employment sectors.

The NEBOSH Fire Safety Certificate aims to build on the success of the National General Certificate. It provides an appropriate breadth of underpinning knowledge for non-specialists in fire safety to enable them to discharge more effectively their organisational duties or functions with respect to workplace fire safety. The course has been designed for managers, supervisors, employee representatives and others who are required to conduct and review risk assessments and fire preventative and protective measures within the workplace.

This International Practitioners of Holistic Medicine accredited qualification teaches the skills, knowledge and competence required of an individual in order to work with clients on specific breathing techniques in both 1:1 or group sessions. Learners will cover: The anatomy of the lungs; gaseous exchange; the breath-brain connection and the physical and mental benefits of breathwork. How to hold space for breathwork; creating a trauma-informed space and basic facilitation skills. How the breath impacts the vagus nerve and its connection to the parasympathetic nervous system. The structure of a breathwork session and how to build momentum with music and motivational cueing (i.e.what to say and what to play). The content of a breathwork session with an in-depth study of 6 unique breathwork exercises. Advanced Facilitation skills – How to plan for emotional and physical reactions; how to modify for different audiences/special populations.

YMCA Level 3 Award in Programming and Supervising Exercise with Disabled Clients

(7)By Platinum Training Institute

This qualification is aimed to give the individuals the skills and knowledge required to programme, supervise and induct a safe and effective programme for disabled clients.

The purpose of these qualifications is to enable learners to coach clients – one to one and in small groups – towards their health and fitness goals. Learners will develop the knowledge, skills and behaviours to plan and deliver creative and personalised exercise programmes, provide nutritional advice and support clients with their overall lifestyle management.

This qualification is aimed at learners who wish to work in an unsupervised capacity; planning, instructing and evaluating a safe and effective Pilates session.

The Gold Card Training Programme is the most comprehensive electrician course available. We offer weekday, weekend and evening delivery options. JIB ECS (Gold) Card is quickly becoming a necessity when seeking work on commercial sites, or sub-contracting to larger contractors.

The shortage of electricians has lead to an increased demand nationwide and in turn a sharp rise in salary. Our training solutions can help you gain nationally recognised qualifications such as City & Guilds and NVQ. Not only you will train in state-of-the-art training centres, but you can also have the opportunity to attain the Work Based Performance Units and complete a portfolio of diverse evidence of onsite work.

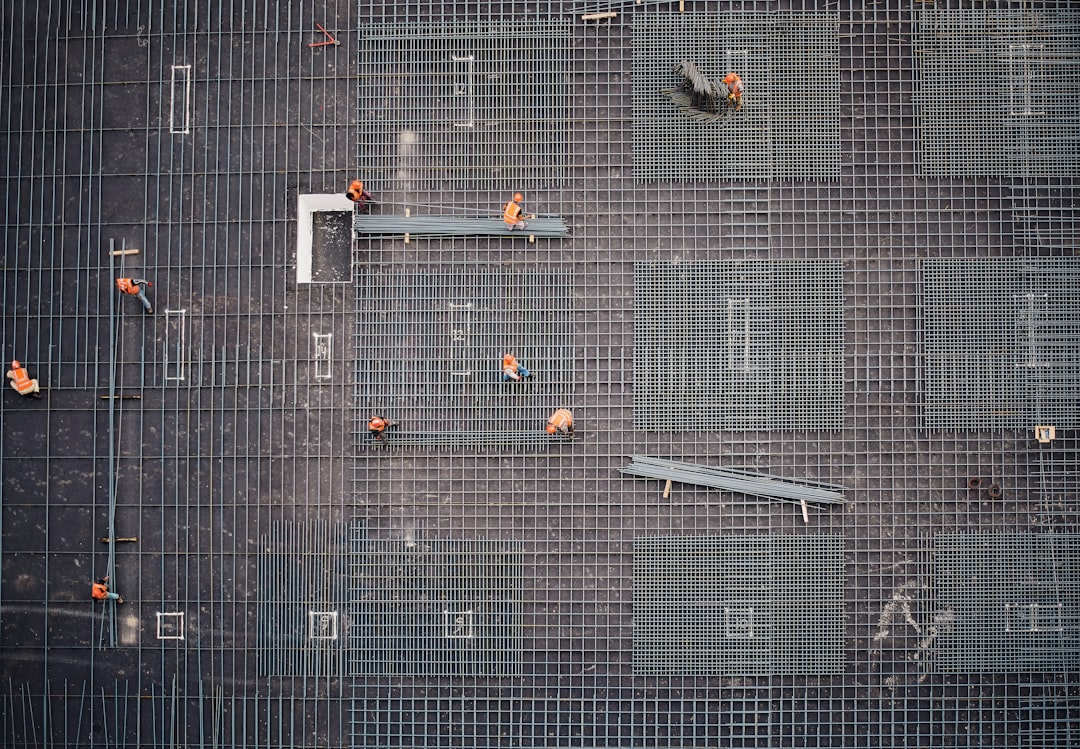

NEBOSH Health and Safety Management for Construction (UK) is guided by legislation but focussed on best practice. With an emphasis on practical application, successful learners will be able to: • Recognise, assess and control a range of common construction hazards • Develop safe systems of work • Take part in incident investigations • Advise on the roles, competencies and duties under construction legislation • Positively influence health and safety culture • Confidently challenge unsafe behaviours • Help manage contractors.