Get a 10% discount on your first order when you use this promo code at checkout: MAY24BAN3X

PENETRATION TESTING TRAINING COURSE DESCRIPTION An advanced technical hands on course focusing on hacking and counter hacking. The course revolves around a series of exercises based on "hacking" into a network (pen testing the network) and then defending against the hacks. WHAT WILL YOU LEARN * Perform penetration tests. * Explain the technical workings of various penetration tests. * Produce reports on results of penetration tests. * Defend against hackers. PENETRATION TESTING TRAINING COURSE DETAILS * Who will benefit: Technical support staff, auditors and security professionals. Staff who are responsible for network infrastructure integrity. * Prerequisites: IP Security IP VPNs * Duration 5 days PENETRATION TESTING TRAINING COURSE CONTENTS * Introduction Hacking concepts, phases, types of attacks, 'White hacking', What is penetration testing? Why use pen testing, black box vs. white box testing, equipment and tools, security lifecycles, counter hacking, pen testing reports, methodologies, legal issues. * Physical security and social engineering Testing access controls, perimeter reviews, location reviews, alarm response testing. Request testing, guided suggestions, trust testing. Social engineering concepts, techniques, counter measures, Identity theft, Impersonation on social media, Footprints through social engineering * Reconnaissance (discovery) Footprinting methodologies, concepts, threats and countermeasures, WHOIS footprinting, Gaining contacts and addresses, DNS queries, NIC queries, ICMP ping sweeping, system and server trails from the target network, information leaks, competitive intelligence. Scanning pen testing. * Gaining access Getting past passwords, password grinding, spoofed tokens, replays, remaining anonymous. * Scanning (enumeration) Gaining OS info, platform info, open port info, application info. Routes used, proxies, firewalking, Port scanning, stealth port scanning, vulnerability scanning, FIN scanning, Xmas tree scanning, Null scanning, spoofed scanning, Scanning beyond IDS. Enumeration concepts, counter measures and enumeration pen testing. * Hacking Hacking webservers, web applications, Wireless networks and mobile platforms. Concepts, threats, methodology, hacking tools and countermeasures. * Trojan, Backdoors, Sniffers, Viruses and Worms Detection, concepts, countermeasures, Pen testing Trojans, backdoors, sniffers and viruses. MAC attacks, DHCP attacks, ARP poisoning, DNS poisoning Anti-Trojan software, Malware analysis Sniffing tools. * Exploiting (testing) vulnerabilities Buffer overflows,, simple exploits, brute force methods, UNIX based, Windows based, specific application vulnerabilities. * DoS/DDoS Concepts, techniques, attack tools, Botnet, countermeasures, protection tools, DoS attack pen testing. * SQL Injection Types and testing, Blind SQL Injection, Injection tools, evasion and countermeasures. * Securing networks 'Hurdles', firewalls, DMZ, stopping port scans, IDS, Honeypots, Router testing, firewall testing, IDS testing, Buffer Overflow. * Cryptography PKI, Encryption algorithms, tools, Email and Disk Encryption. * Information security Document grinding, privacy.

Natural Gas Properties & Sulphur Recovery

By Asia Edge

ABOUT THIS VIRTUAL INSTRUCTOR LED TRAINING (VILT) This 5 half-day VILT course will comprehensively cover the technical aspects of gas processing. The scope will be from the wellhead through the typical gas processing plant and discuss gas gathering (pipeline hydraulics), natural gas treating (H2S, CO2 removal), acid gas injection and sulfur recovery. One unique aspect of this training course is the operations and troubleshooting discussions in each module. This VILT course is suited to technical personnel or technical management. Training Objectives After the completion of this VILT course, participants will be able to: * Grasp the key specifications of natural gas and liquid products * Understand the physical and transport properties of gases and liquids and liquid-vapor phase behavior * Explore the various technologies for processing natural gas and to make the specifications * Examine the design of the technologies * Learn how to diagnose operating problems to keep facilities running reliably Target Audience This VILT course is intended for all surface technical personnel such as process engineers & technologists, facility engineers and production engineers & technologists. This VILT course will greatly benefit but not limited to: * Process, petroleum and production engineers * Field operators and technicians * Personnel involved in gas treatment and processing * Managers and Supervisors involved with gas processing operations Course Level * Basic or Foundation * Intermediate Training Methods The VILT course will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Course Duration: 5 half-day sessions, 4 hours per session (20 hours in total). The maximum number of participants for this course is 20 persons. Case studies and Exercises: This VILT course will use actual case references throughout its duration in various forms. This will allow the application of the participants' newly-acquired knowledge. Case studies also stimulate independent thinking and discussion among the participants Trainer Your expert course leader has written several papers that have been published in both academic and industry journals. He has over 30 years of industry experience, specializing in gas processing (pipeline hydraulics, separation, dehydration, treating, sulphur recovery and refrigeration processes) and also has experience with crude oil dehydration, stabilization and micro-refining topping plants. He has experience with developing new technology and is recently involved in lithium, waste biomass and used motor oil pyrolysis and geothermal projects. He has recognized expertise in thermodynamics and physical and transport properties of fluids. He has consulted for several EPC and operating companies through his company Chem-Pet Process Tech., and currently holds the role of Director of Technology in an integrated engineering and solutions provider to the energy industry. He is currently involved with a small power-based carbon capture project as well as helping clients determine the best options for utilities decisions. He has been involved with CO2 dehydration and CO2 flood gas treating as well as acid gas injection projects for several years. Highlighted Achievements: * Developed ORC geothermal model to determine the available power from wells in Alberta * Acting on the Technical Advisory Board for E3 Metals, extracting lithium from formation water. * Acted as a Subject Matter Expert for assessing the performance of the Plains Midstream Canada, Empress 1 Deep Cut Straddle Plant in a potential litigation. * Acted as an Expert Witness for JL Transportation patent defence of a dense phase technology. * Process engineer lead on the addition of the new Orloff gas plant for Deltastream. Also troubleshooted the oil battery shipping pump, plate exchanger and FWKO and treater. * Evaluated gas processing and sulphur recovery options for new feeds to the Zhaikmunai Zelenovsky Gas Plant, Kazakhstan (with PM Lucas, Serbia). * Completed capacity analysis for hydrocarbon dew point versus liquid recovery of three trains at Birchcliff Pouce Coupe facility including amine unit, refrigerated gas plant and acid gas injection. * Completed process design for CO2 flue gas dehydration for Husky Energy Inc (with Status Engineering) * Provided simulations of EnCana Foster Creek and Christina Lake and Husky McMullen SAGD facilities (with Vista Projects). Performed process engineering for Cenovus Pelican Lake SAGD pilot (with GRB Engineering) Bear Lake heavy oil polymer injection pilot (with GRB Engineering). * Lead process engineer on the design of IEC Kerrobert crude oil micro-refinery (topping plant). * Provided engineering support and troubleshooting for Enerchem Slave Lake Crude tower and product blending (with Status Engineering). POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

TOTAL SIPP COURSE DESCRIPTION SIPp is a robust performance testing tool designed for evaluating the SIP protocol. This comprehensive course takes you on a journey from the initial installation of SIPp to mastering fundamental scenarios, exploring diverse architectures, delving into statistics analysis, and crafting XML scenario files. WHAT WILL YOU LEARN * Monitor SIP traffic with SIPp. * Use SIPp for performance testing. * Use the standard SIPp scenarios. * Create custom scenarios in XML for SIPp. TOTAL SIPP COURSE DETAILS * Who will benefit: Those working with SIP. * Prerequisites: Definitive SIP for engineers * Duration 2 days TOTAL SIPP COURSE CONTENTS * Introduction What is SIPp? SIP review: UAC, UAS, INVITE, BYE. Sample SIP call flows. Hands on Wireshark, SIP call flow. * Installing SIPp Getting SIPp, installing SIPp. * Using SIPp Running sipp. sipp with uas scenario, sipp with uac scenario. The integrated scenarios. Online help. Hands on uac, uas. * Controlling SIPp Hot keys, commands, UDP socket. Running SIPp in the background. Traffic control. SIPp performance testing. Hands on Changing call rates, remote control, pausing traffic. * Monitoring SIP traffic Scenario screen, statistics. Response times, counters. Hands on Monitoring SIP traffic. * More integrated scenarios SIPp and media and RTP. 3PCC. 3PCC extended. Transport modes: UDP, TCP, TLS, SCTP, IPv6 mono and multi socket. Hands on Third Party Call Control. * XML What is XML? Content, markup, elements, attributes. Start tags, end tags. Hands on Displaying embedded scenarios, looking at the XML files of the integrated scenarios. * Creating your own XML scenarios scenario, message commands, send, recv, nop, pause, sendCmd, recvCmd, common sipp scenario attributes, command specific sipp scenario attributes. XML DTD, jEdit. Hands on uac and uas scenario XML files. * Recv actions Log and warning, exec, variables, variable types, variable scope. External variables. Hands on RTP streaming, Change a calls network destination, injection files. * Regular expressions What is an RE. POSIX 1003.2. Re injection. Validation. Hands on regex example.

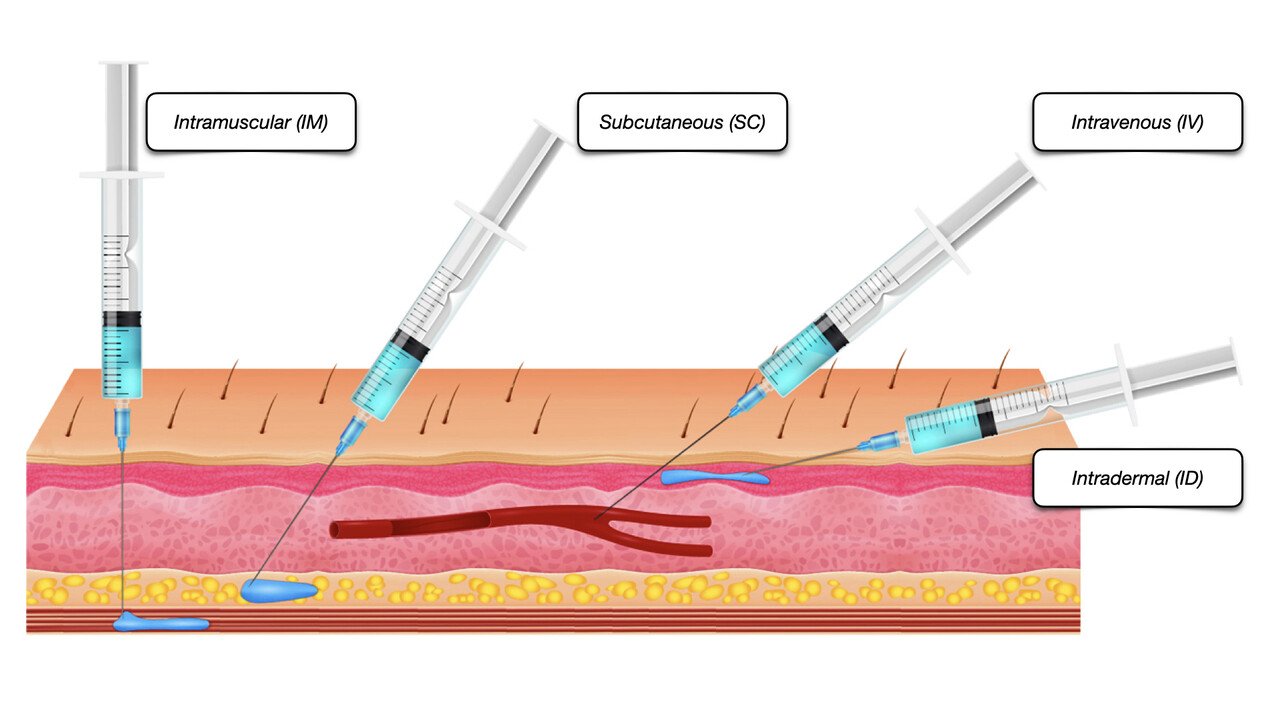

An Understanding of Injectable LHRH agonists

By Guardian Angels Training

Gain comprehensive knowledge on injectable LHRH agonists with our course. Learn about mechanisms, clinical applications, administration techniques, and more.

Combustion Engineering for Coal Fired Power Plants

By Asia Edge

ABOUT THIS TRAINING COURSE This 5 full-day course provides detailed description of all combustion equipment and systems used in pulverized coal boilers and circulating fluidized bed (CFB) boilers including pulverized coal burning systems, coal feeder, pulverizer and classifier, pulverized coal burners, furnace and fans. This course provides also a comprehensive explanation of all boiler combustion control systems including pulverizer control system, combustion control, control of coal and air flow into the boiler, furnace pressure control, oxygen trim control, nitrogen oxides (NOx) and sulfur oxides (SOx) control, control of ammonia injection, flue gas dew point control, purge control, flame monitoring and tripping system as well as their tuning methods. All boiler control systems are covered as well in this course including drum level feedwater control, main steam and reheat steam temperature control, boiler limits and runback, sliding or variable pressure control, heat rate optimization with sliding pressure control, boiler-turbine coordinated control, etc. The course provides also detailed explanation of Boiler NFPA 85 Code (Boiler and Combustion Systems Hazards Codes) and American National Standard Institute/Instrument Society of America Code (ANSI/ISA-77-44-01-2007 Code). The burner management systems (BMS) and examples of boiler permissive starting logic and protective tripping logic will be explained thoroughly. The various methods used to calculate the boiler efficiency are covered in detail in this course including the direct and indirect methods. All the factors which affect the efficiency and emissions of pulverized coal boiler and CFB boiler will be explained thoroughly. The course covers also all the methods used to improve the efficiency of pulverized coal boilers and CFB boilers including improvement to their combustion efficiency and control systems performance. Training Objectives * Boiler Combustion Equipment and Systems: Gain an in-depth understanding of all boiler combustion equipment and systems including pulverized coal burning systems, coal feeder, pulverizer and classifier, pulverized coal burners, furnace and fans * Boiler Combustion Control Systems: Gain a thorough understanding of all boiler combustion control systems for pulverized coal boilers, and CFB boilers including pulverizer control system, combustion control, control of coal and air flow into the boiler, furnace pressure control, oxygen trim control, nitrogen oxides (NOx) and sulfur oxides (SOx) control, control of ammonia injection, flue gas dew point control, purge control, flame monitoring and tripping system * Boiler Conventional Control Systems: Gain an in-depth understanding of all boiler conventional control systems including drum level feedwater control, main steam and reheat steam temperature control, boiler limits and runback, sliding or variable pressure control, heat rate optimization with sliding pressure control, and boiler-turbine coordinated control * Boiler NFPA 85 Code (Boiler and Combustion Systems Hazards Codes) and American National Standard Institute/Instrument Society of America Code (ANSI/ISA-77-44-01-2007 Code): Learn about NFPA 85 code and ANSI/ISA-77-44-01-2007 code * Burner Management System and Boiler Permissive Starting Logic and Protective Tripping Logic: Gain an in-depth understanding of burner management system and boiler permissive starting logic and protective tripping logic * Boiler Efficiency Calculations: Learn how to calculate the boiler efficiency using the direct and indirect methods * Factors Affecting the Efficiency and Emissions of Boilers: Understand all the factors which affect the boiler efficiency and emissions * Methods Used to Improve the Efficiency of Boilers: Learn about all the methods used to improve the efficiency of pulverized coal boilers, and CFB boilers including improvement to their combustion efficiency and control systems performance * Boiler Instrument and Piping Diagrams: Gain an in-depth understanding of all boiler instrument and piping diagrams * CFB and Pulverized Coal Boilers Equipment and Systems: Learn about various types of equipment and systems used in CFB and pulverized coal boilers including economizers, steam drum, superheaters, air preheaters, ammonia injection systems, etc. Target Audience * Engineers of all disciplines * Managers * Technicians * Maintenance personnel * Other technical individuals Course Level * Basic or Foundation Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: * Excerpt of the relevant chapters from the 'POWER GENERATION HANDBOOK' second edition published by McGraw-Hill in 2012 (800 pages) * Excerpt of the relevant chapters from the 'POWER PLANT EQUIPMENT OPERATION AND MAINTENANCE GUIDE' published by McGraw-Hill in 2012 (800 pages) * COMBUSTION ENGINEERING FOR COAL FIRED POWER PLANTS MANUAL (includes practical information about combustion engineering for coal fired power plants - 550 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; * Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. * Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. * Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. * Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). * Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: * The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 * The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). * The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). * Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

The Emergency treatment of Adrenal Crisis

By Guardian Angels Training

Gain essential knowledge and skills to recognise, manage, and provide prompt emergency treatment for adrenal crisis with our course. Ideal for healthcare professionals.

NETWORK FORENSICS TRAINING COURSE DESCRIPTION This course studies network forensics-monitoring and analysis of network traffic for information gathering, intrusion detection and legal evidence. We focus on the technical aspects of network forensics rather than other skills such as incident response procedures etc.. Hands on sessions follow all the major sections. WHAT WILL YOU LEARN * Recognise network forensic data sources. * Perform network forensics using: Wireshark NetFlow Log analysis * Describe issues such as encryption. NETWORK FORENSICS TRAINING COURSE DETAILS * Who will benefit: Technical network and/or security staff. * Prerequisites: TCP/IP foundation for engineers. * Duration 3 days NETWORK FORENSICS TRAINING COURSE CONTENTS * What is network forensics? What it is, host vs network forensics, purposes, legal implications, network devices, network data sources, investigation tools. Hands on whois, DNS queries. * Host side network forensics Services, connections tools. Hands on Windows services, Linux daemons, netstat, ifoconfig/ipconfig, ps and Process explorer, ntop, arp, resource monitor. * Packet capture and analysis Network forensics with Wireshark, Taps, NetworkMiner. Hands on Performing Network Traffic Analysis using NetworkMiner and Wireshark. * Attacks DOS attacks, SYN floods, vulnerability exploits, ARP and DNS poisoning, application attacks, DNS ANY requests, buffer overflow attacks, SQL injection attack, attack evasion with fragmentation. Hands on Detecting scans, using nmap, identifying attack tools. * Calculating location Timezones, whois, traceroute, geolocation. Wifi positioning. Hands on Wireshark with GeoIP lookup. * Data collection NetFlow, sflow, logging, splunk, splunk patterns, GRR. HTTP proxies. Hands on NetFlow configuration, NetFlow analysis. * The role of IDS, firewalls and logs Host based vs network based, IDS detection styles, IDS architectures, alerting. Snort. syslog-ng. Microsoft log parser. Hands on syslog, Windows Event viewer. * Correlation Time synchronisation, capture times, log aggregation and management, timelines. Hands on Wireshark conversations. * Other considerations Tunnelling, encryption, cloud computing, TOR. Hands on TLS handshake in Wireshark.

Carbon Capture and Storage (CCS): Project Risks & How to Manage Them

By Asia Edge

ABOUT THIS VIRTUAL INSTRUCTOR LED TRAINING (VILT) Governments, regulators and energy companies are pursuing CO2 storage technologies to meet their net-zero carbon commitments as well as targets set by the international Paris Agreement on climate change. For successfully executing Carbon Capture & Storage (CCS) projects, various technical, operational, economic and environmental risks and associated stakeholders need to be managed. In this 5 half-day Virtual Instructor Led Training (VILT) course, the methods for managing risk in CCS projects are addressed with a focus on CO2 injection and storage. The VILT course will also demonstrate how to assess storage capacity of a potential CO2 storage reservoir, model framing techniques, and well injectivity issues related to CO2 injection. The potential leak paths will be discussed such as reservoir seals, leakage along faults and aspects of well integrity. In the VILT course, the design of a monitoring programme will also be discussed. The VILT course will be supported by various case studies. This VILT course will cover the following modules: 1. CCS projects in an international context 2. Site selection and site characterization 3. Storage capacity assessment 4. Injectivity assessment 5. Containment assessment 6. Measurement, monitoring & verification Training Objectives On completion of this VILT course, participants will be able to: * Uncover the functions and associated components required to capture, transport and store CO2 in subsurface aquifers and (depleted) hydrocarbon reservoirs * Find a systematic and integrated approach to risk identification and assessment for CO2 storage projects (maturation) * Appreciate the requirements (physics modelling) and uncertainties to assess the CO2 storage capacity of a selected site. * Understand the challenges, data and methods to assess CO2 well injectivity and well integrity * Identify the leakage pathways of a selected storage site, and understand the assessment methods and associated uncertainties * Learn how to design a monitoring program Target Audience This VILT course is intended for all surface and subsurface engineers such as facility engineers, geologists, geophysicists, reservoir engineers, petrophysicists, production technologists/engineers, well engineers and geomechanical specialists. Also, (sub)surface team leads, project managers, business opportunity managers, decision executives, and technical risk assessment & assurance specialists will benefit from this VILT course as it provides a common framework and workflow to develop a CCS project. For each class, it is highly recommended that a mix of disciplines mentioned above are represented to facilitate discussions from different perspectives. Course Level * Basic or Foundation Training Methods This VILT course is built around cases in which teams work to identify and assess CO2 storage site issues using a systematic thought approach in this course. In addition, exercises are used to practise the aspects of the CCS risk assessment process. The VILT course provides a venue for discussion and sharing of good practices as well as opportunities to practise multi-discipline co-operation and facilitation. Participants are encouraged to bring their own work issues and challenges and seek advice from the expert course leaders and other participants about all aspects of CCS. This VILT course will be delivered online in 5 half-day sessions comprising 4 hours per day, with 2 breaks of 10 minutes per day. Trainer Trainer 1: Your expert course leader has more than 36 years of experience in the oil & gas industry with Shell. He gained broad experience in petroleum engineering, with expertise in integrated production systems from subsurface, wells and surface. He has had assignments in Production Technology, R&D, Production Chemistry, Rock Mechanics and Reservoir Engineering cEOR, with a proven track record in technology screening, development and deployment, field development planning, conceptual well design and Production System Optimization (PSO) of gas and oil fields as well as preparing Well, Reservoir & Facility Management (WRFM) strategies and plans. He had also worked on assignments in NAM and did fieldwork in Oman, Gabon and Shell Nigeria. He is a skilled workshop facilitator. He discovered his passion for teaching following an assignment in Shell Learning. During his time in Shell, he developed and taught technical courses to Shell professionals via blended learning. Trainer 2: Your second expert course leader has over 30 years of experience identifying, assessing and mitigating technical risks with Shell. The main focal point of his experience is in subsurface and Geomechanical risks. He is the the founding father of various innovations in how we assess risks by tool development (for bore hole stability, 3D geomechanical field evaluations and probabilistic assessment). He also developed an eye for people motivation, change management and facilitation. He was also responsible for the Geomechanical competence framework, and associated virtual and classroom training programme in Shell for 10 years. Trainer 3: Your third expert course leader has more than 30 years of experience in Shell, focusing on research and development in drilling and offshore systems. His areas of expertise is in project management, finance, business planning, investment, development studies and economics models. In 2021, he worked on a project that looked into the economic evaluation of P18A field complex for CO2 storage. He has an MSc in Mechanical Engineering (M.E.) TU Delft Netherlands (Hons) and a baccalaureate from Erasmus University Rotterdam. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

CO2 Transportation From Capture to Storage and Usage

By Asia Edge

ABOUT THIS TRAINING COURSE This 5-days comprehensive training course provides not only an introduction into the issues associated with the development of the pipeline transportation of CO2 from its Capture, it's transportation, storage and usage but also provides an in depth understanding of the issues to be considered in the development, design and operations of these pipelines. The theme throughout this training course is CO2 Flow Assurance and Innovative Technologies. Each training day will consist of lectures in the morning and a hands-on workshop in the afternoon. The workshop allows the participants to appreciate the design process associated with CO2 transport and its operations. Various software will be available during the workshop to predict thermo hydraulics and associated phase flows through CO2 pipelines and the attached infrastructure. Further software to assess surge and environmental safety will also be available. The CO2 pipeline design approach will consider an integrated solution through modelling the CO2 capture system as well as the host storage facility. The participants will have a total appreciation of the methodology required to develop a CO2 transportation system and have an understanding of all of the Flow Assurance, risks, and operating issues and technology requirements. Training Objectives After the completion of this training course, participants will be able to: * Understand the process required and identify data to analyse Flow Assurance for CO2 pipeline transport * Review and Identify the Flow Assurance issues required to be evaluated for CO2 pipeline transport design and operations methodology. These include; Hydrates, Slugging, Corrosion, Scaling, Fluid Phase Behaviour and transient conditions * Establish the studies to be undertaken for each area of CO2 transport including 'Rules of Thumb' and software to be used * Comprehend the need for innovative methods and the technologies to mitigate Flow Assurance issues and the need for economics considerations * Appreciate the need for an integrated analysis of the CO2 transport system from the CO2 capture to the host storage facility * Gain an appreciation of the emerging and enabling technologies for CO2 transport and storage application * Dive deeper into the operational strategies requirements to mitigate Flow Assurance issues Target Audience This training course is suitable and will greatly benefit the following specific groups: * Reservoir Engineers * Flow Assurance Engineers * Thermodynamics Engineers * Process and Chemical Engineers * Pipeline Engineers * Facilities Engineers * Control and Subsea Engineers working in the Oil and Gas industries * Engineers in other disciplines may attend that require an appreciation of CO2 pipeline transport * Control and Subsea Engineers working in the Oil and Gas industries * Engineers in other disciplines may attend that require an appreciation of CO2 pipeline transport Course Level * Intermediate Training Methods The training instructor relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all the topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught in their own organization. Course Duration: 5 days in total (35 hours). Training Schedule 0830 - Registration 0900 - Start of training 1030 - Morning Break 1045 - Training recommences 1230 - Lunch Break 1330 - Training recommences 1515 - Evening break 1530 - Training recommences 1700 - End of Training Course delivery: * The maximum number of participants allowed for this training course is 20. * A basic understanding of thermo-hydraulics would be advantageous. * Morning Lectures and afternoon hands-on practical workshop. Special features: * PC-based simulation software demonstration * Workshop for hands-on training * Course References & Additional resources: * 'CO2 Transport from Capture to Storage and Usage', 1st Edition * Handouts * Pre & Post Assessment Trainer Your expert course leader is a renowned specialist in flow assurance management for the oil & gas field developments. His expertise enables him to support the operating and contracting companies as well as financial institutions regarding due diligence on offshore development investment decisions and associated operational system risks. Technical assessment of fields for acquisition and production enhancement opportunity. He possesses specialist expertise in evaluating difficult pipeline fluids transport such as Ethylene, Carbon Dioxide and Hydrogen through feasibility studies and technical reviews for clients. He has an exceptional academic background and natural leadership abilities are supported by practical experience of diverse projects worldwide, along with numerous publications at key conferences and publication of four books. Particular interests in developing novel and innovative technologies for subsea applications to solve difficult flow assurance problem areas and improve field development economics. He has worked on major industry projects including; Concorde aircraft fuelling system, the Channel Tunnel aerodynamics and the first deep water oil field development (Foinaven) in the West of Shetland. He is also currently developing a renewable energy solar farm and carbon neutral energy crop (Miscanthus) for domestic and commercial power generation application. He has developed in-house resources including specialist oil & gas field development evaluation software for subsea and onshore field infrastructure development options including; costing and financial analysis, reservoir viability, flow assurance assessment, subsea processing and boosting technologies, flow induced vibrations, surge analysis, heat transfer and chemical injection systems. Patents: · Subsea Seabed Power Generation for Depleting Gas fields Using Renewable Energy · Gas to Liquids Absorption Technology (GTLA) for subsea and onshore Flow Assurance applications · Subsea Gas Compressor System using pigs and liquid pumps · Pressure Boosting using water injection pumps · B&W Mentor subsea multi-phase meter · Surge suppression using a contained gas method for pipeline systems POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Search By Location

- Injection Courses in London

- Injection Courses in Birmingham

- Injection Courses in Glasgow

- Injection Courses in Liverpool

- Injection Courses in Bristol

- Injection Courses in Manchester

- Injection Courses in Sheffield

- Injection Courses in Leeds

- Injection Courses in Edinburgh

- Injection Courses in Leicester

- Injection Courses in Coventry

- Injection Courses in Bradford

- Injection Courses in Cardiff

- Injection Courses in Belfast

- Injection Courses in Nottingham