79 EMIS courses

Get a 10% discount on your first order when you use this promo code at checkout: MAY24BAN3X

Alternative Energy Technology Course

By Hi-Tech Training

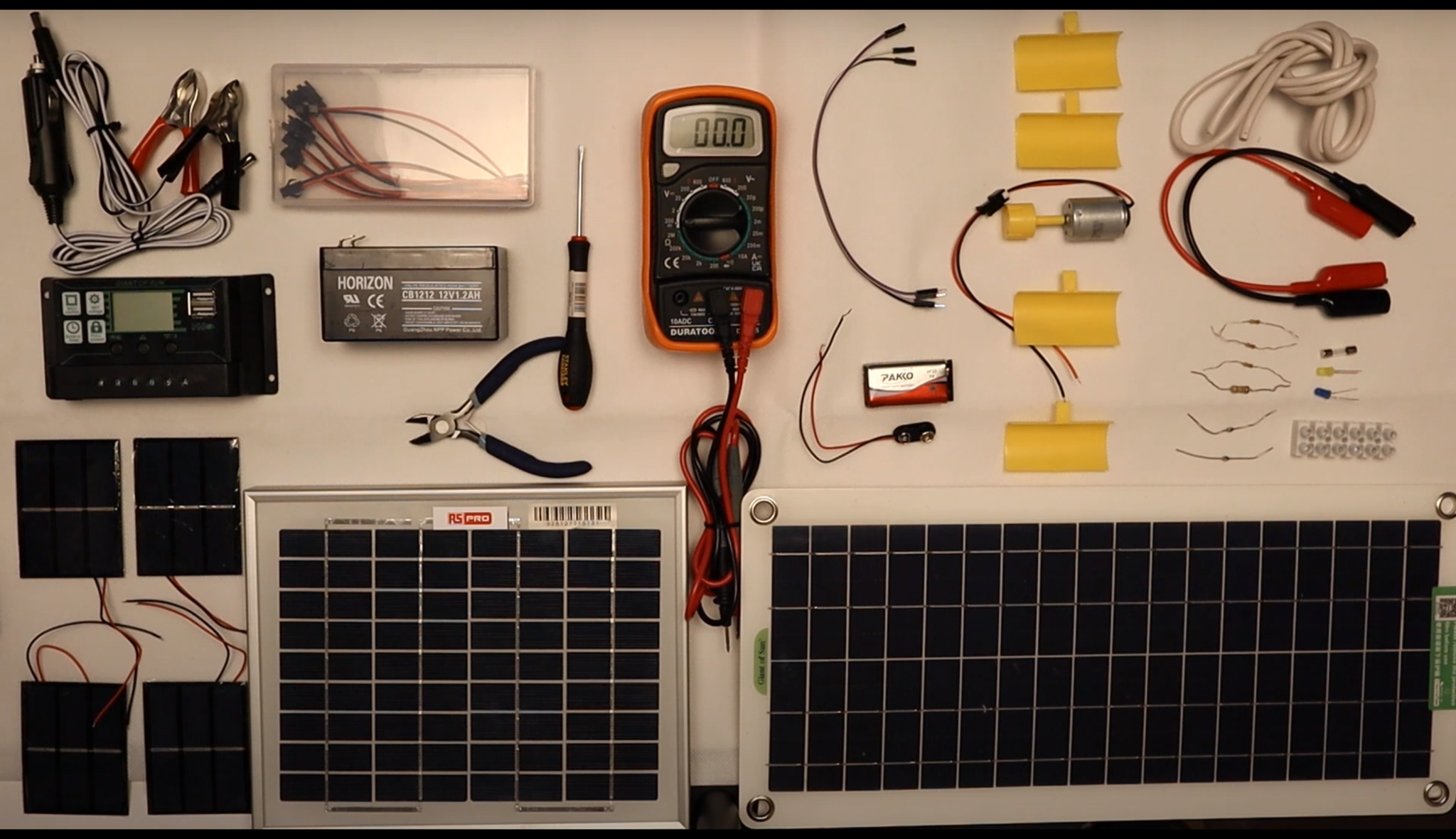

AIM The Alternative Energy Technology Course is a practically based alternative energy course designed to give participants an understanding of alternative energy options and provide them with that practical knowledge and skills to build solar to electric and wind to electric systems at a foundation level. The course is designed to be of benefit to people either working or intending to work as:- Alternative Energy Installers or anyone just wishing to gain practical knowledge of Practical Alternative Energy Systems. DURATION AND SCHEDULE The Alternative Energy Technology commences on Monday 29th April at 7.00pm and takes place from 7.00pm – 10.00pm every Monday and Wednesday evening for the duration of the 5-week Course. A payment of £65 secures your place on your chosen course. The balance of the course fees of £600 can be paid shortly before course commencement. ONLINE VIRTUAL CLASSROOM – HOW IT WORKS? The course will be delivered through blended training consisting of 10 online virtual classroom sessions. The 10th and last session will involve the written examination and assessments. During the virtual classroom sessions, Trainees will have a live video feed with their instructor talking to them, doing practical live demonstrations on equipment being involved actively in the learning). In preparation for this, we plan to have a quick informal free online meeting prior to course commencement for about an hour just to make sure that people get connected through Zoom properly, let them know what the virtual classroom will be like and go through any questions they may have. To join the virtual sessions, you will need a PC/Laptop or Tablet with an internet connection. Joining instructions (login IDs, etc.) will be sent before the Informal Induction session. LEARNING OBJECTIVES * Consider the advantages and disadvantages of the different alternative energy systems * Demonstrate a knowledge of the operation of a wide range of electronic components and circuits and their applications in Alternative Energy Systems * Become competent in the correct use of electronic test and measurement equipment such as Analogue and Digital Multimeters * Build a simple photovoltaic to electric system * Build a simple wind to electric system * Effectively connect up, test and fault-find system elements COURSE CONTENT * Alternative Energy: – Introduction, terminology, types and applications * Using technology to reduce CO2 emissions and energy costs * Advantages and disadvantages of the various types of alternative energy including Solar Thermal Energy, Hydro Energy, Biomass Energy, Geothermal Heating. * Terms: – Source, Renewable, Sustainable, Photovoltaic, Carbon neutral, Active/Passive * Sustainability Issues, Health & Safety and Environmental precautions. * Introduction to Electronics: – Electric Current, OHMS Law, Insulation, Conduction, Kilowatt-hours, and related power calculations and formulae. Fuses and trip switches. Wiring techniques. Practical uses of commonly used components e.g. diodes, relays, transformers * Become competent in the correct use of electronic test and measurement equipment such as Analogue and Digital Multimeters, Battery Test Meters. * Inverters; – types, uses, ratings, calculations, connection s * Connections to electrical devices * Calculating loads and selecting battery ampere-hour capacity * Construct, test and fault find a Wind energy harnessing system * Construct, test and fault find a Solar energy harnessing system * Determine using online data sources the effective performance of systems at different global locations and seasonal variations * Sustainable and Energy Efficient Building Design * Relevant standards and issues, Changing technology and keeping updated CERTIFICATION On completion of the Course, having been successful in TWO examinations (one written, one practical) the participant will receive a Hi-Tech Training Certificate stating the Grade obtained, be it: PASS, CREDIT or DISTINCTION. PASS = 50% – 64%. CREDIT = 65 – 79%. DISTINCTION = 80% – 100%.

VTCT LEVEL 4 CERTIFICATE IN LASER AND INTENSE PULSED LIGHT (IPL)

By The Angel Academy Of Teaching & Training

Intense Pulsed Light or Laser Hair Removal. Hugely popular in the UK, this treatment leads the way in permanent hair removal. Salons around the UK command very good profits from a course of IPL or laser. In the 2000's, women have the opportunity to be hair free and this has led to an increase in the demand for hair free bodies. Certain cultures dictate that women be as hair free as possible and IPL allows for this. There are certain IPL machines in the market that are virtually pain free, making it possible for a woman to have a 'brazilian' or a 'hollywood' treatment. Please enquire if you wish to know more. -------------------------------------------------------------------------------- HOW DOES IPL WORK The treatment involves the application of a focused, broad-spectrumlight (xenon), which is applied to the surface of the skin using a hand-held application head. Selective photo-thermolysis involves the process of the light, which travels across and within the range until it reaches the hair shafts or the root of the hair (the bulb). The bulb is usually where the highest concentration of melanin is located. The melanin is what determines our hair/skin colour and once this melanin has been destroyed there can be no growth. The IPL light is changes into heat. This will literally 'blow up' the root of the hair. If a hair has nowhere to grow with no hair bed, it cannot grow! This intense heat also destroys the papilla. IPL treatments will permanently reduce the total number of body hairs but will not result in a permanent removal of all hair and many factors can trigger re-growth such as hormones, menopause, pregnancy and medication. With an IPL treatment, the hair growth cycle has to be in Anagen (the active stage). The hair growth cycle differs on different areas of the body which is why we need to recommend a course! A- Anagen (active stage) C- Catagen (transitionary stage) T- Telagen (resting phase) As the hair growth cycle process can take between 4-6 weeks, this is why we recommend a client to return for their course every 4 weeks. It has the best track record. IPL & Laser has the best overall results (on large areas), versus any other method, in getting rid of hair for longer periods of time if not permanently. All skin types and hair colours can be identified. IPL (intense pulsed light) it does target pigmentation (this determines hair and skin colour), but an ND Yag Laser is not determined by the Fitzpatrick Scale. WHAT IS THE DIFFERENCE BETWEEN LASER AND IPL Laser and IPL are identified by their wavelength which is usually shown in nanometres (nm). IPL systems are different to a Laser machine as they have a range of emissions. With the AATT Freeze 1 machine the range for hair removal is 640-1200nm (this is a ruby wavelength). For photo-rejuvenation the range is 540-1100nm (this is a green wavelength). The Poly lightbulb emits a range of wavelengths to appear as a flash of white light The Wavelengths are incoherent and travel in all directions with no order between them The High beam spreads out more rapidly than a laser beam The Focus is on a large area which reduces the risk of eye damage compared with coherent sources such as a laser beam. IPL is the abbreviation of Intense Pulsed Light. The machines have been widespread in use since the beginning of the 1990's. The flash lamp is commonly a xenon (huge uses across industry, photographic and medical) WHAT DOES THE COURSE INCLUDE? When choosing a course ensure that it includes both theory and a wide variety of practical content. Every course should include: * Anatomy and Physiology * Types & structure of the hair * Health & Safety Management * Salon Management * Client Care * Laser & IPL Hair Removal Application * Laser and IPL for Photo-rejuvenation * Skin, blood and lymphatic circulation * Reproductive and endocrine system * Theory of Electric Currents * Consultations & Record Cards * Contra-indications & contra-actions * Aftercare advice * Accurate techniques * Legislation, Hygiene and Sterilisation WHAT IS EXPECTED OF THE STUDENT TO COMPLETE A FAST TRACK COURSE? * Full attendance of the lesson dates * A full commitment to work hard * Health & Safety Management * Salon Management * Client Care * Successful Laser & IPL Hair Removal Application * Successful Laser and IPL for Photo-rejuvenation * Completion of a Portfolio * Performing Competent Assessments * Producing a Written Assignment * Home Study and Practice Please see below our list of upcoming courses. Click on the course for further information, request a call or email regarding the course or book now! CourseDaysDatesCostVTCT Level 4 IPL & Laser26/04/20247/04/2024£999 VTCT Level 4 IPL & Laser223/05/202424/05/2024£999 VTCT Level 4 IPL & Laser221/06/202422/06/2024£999 VTCT Level 4 IPL & Laser224/07/202425/07/2024£999

The Fundamentals of Ultra-Low Emission Road Transport

By Cenex (Centre of Excellence for Low Carbon & Fuel Cell Technologies)

In-house training courses on electric and hydrogen vehicle technologies, charging infrastructure and how they work.

Upstream Decarbonization: Strategies & Measures towards Lowering Emissions

By Asia Edge

ABOUT THIS TRAINING Decarbonization of the Upstream Oil & Gas sector has previously been based on inter-fuel competition. Market actions were seen as the most effective method for reducing the level of emissions. However, the pace of decarbonization is now being led by government policy acting in concert with a coalition of stakeholders such as investors and consumers. The primary focus of this pathway is on the management of carbon emissions to both mitigate and adapt to climate change. Some energy analysts have forecast that global production of oil and natural gas will have to decline annually by 4 to 6 percent in order to meet the global target of Net Zero Emissions by 2050. Oil and gas producers face a difficult challenge in deciding upon the strategy and measures that will best achieve targets set for them while maintaining supply, attracting investments and accessing markets. This 2-day training course will provide participants with an understanding of the strategies and measures for decarbonizing the Upstream Oil and Gas sector within the framework of measures implemented by individual governments through their respective commitments to reduce emissions to achieve their National Determined Contribution under the Paris Agreement. This course offers a unique opportunity to understand the rapidly increasing issues confronting the industry as well as the options for the management of carbon emissions to comply with corporate as well as national policies and the implementation of measures for controlling, reporting and verification. Training Objectives Upon completion of this course, participants will be better equipped to participate in the implementation of measures for the management of carbon emissions in the following areas: * Implementation of measures for reducing carbon emissions * Establishing systems for monitoring and reporting carbon emissions * Evaluating the commerciality of discoveries * Reviewing and strategizing future field development plans * Meeting Environmental Obligations Target Audience This course has been specifically designed for professionals involved in the international oil and gas industry, whether employed a field operator, national oil company, or government. It offers a unique opportunity to rapidly increase your understanding of the issues confronting the industry as well as the options for the management of carbon emissions to comply with corporate as well as national policies and the implementation of measures for controlling, reporting and verification. Staff with the following roles will find this course particularly useful: * Corporate Planners * Project Engineers * Financial Analysts * Environmental Specialists * Legal Advisors * Regulatory & Compliance Officers Course Level * Basic or Foundation Trainer Your expert course leader is an international legal expert in petroleum law who has been listed in the Guide to the World's Leading Energy and Natural Resources Lawyers. In his thirty years of practice, he has been the lead negotiator and acquisitions advisor for oil and gas companies in the US and the Asia-Pacific. These transactions have included both upstream (licences and leases) and downstream (refineries and pipelines) assets. He has been appointed as Distinguished Visiting Professor in Oil and Gas at the University of Wyoming and Honorary Professor at the Centre for Energy, Petroleum & Mineral Law & Policy (CEPMLP) at Dundee University. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

The NEBOSH General Certificate qualification has been recognised for many years as an excellent introduction to the fundamentals of occupational health and safety. The NEBOSH Environmental Management Certificate is designed to provide a similarly sound foundation in environmental management.

Carbon Capture, Utilization & Storage (CCUS)

By Asia Edge

ABOUT THIS VIRTUAL INSTRUCTOR LED TRAINING (VILT) This 5 half-day Virtual Instructor Led Training (VILT) course covers carbon capture and geological storage of carbon dioxide. Burning fossil fuels for energy is a major source of carbon dioxide emissions to the atmosphere. Most anthropogenic (man-made) carbon dioxide is emitted by coal-fired or gas-fired power plants, and significant quantities of carbon dioxide are emitted through the production and separation of carbon dioxide-rich natural gas and industries such as cement, iron and steel. Carbon Capture Utilization and Storage, or CCUS, involves the long-term storage of captured carbon dioxide emissions in subsurface geologic formations. This VILT course covers all aspects of CCUS including transport, storage and monitoring, economics and community engagement. It explores in detail the challenges of the current technology of geological storage, monitoring and verification including examples from working projects around the world. Many of these technologies are commonly employed by the petroleum industry. Successful deployment of CCUS will also require economic incentives, appropriate regulation, clarity on liability issues and acceptance by the community. These aspects of CCUS, and the corresponding opportunities for appropriately skilled organisations and individuals also will be discussed. Course Content at a Glance 1. Context for CCS/CCUS as An Emissions-reduction Measure 2. Principles of Geological Storage 3. Finding Geological Storage Sites 4. Stationary Sources of Carbon Dioxide for Capture 5. Carbon Dioxide Capture Technologies 6. Compression and Transport of Carbon Dioxide 7. Economics of CCS/CCUS 8. Community, Safety, Legal & Regulatory Issues 9. Risk Assessment Training Objectives Upon completion of this VILT course, participants will be able to: * Identify the need for Carbon Capture and Storage (CCS) * Outline the key steps in the Carbon Capture and Storage process * Distinguish between reservoir rocks and sealing rocks * Describe the importance of permeability and porosity to storing carbon dioxide * Contrast the geological structures and trapping mechanisms for storing carbon dioxide * Describe the changes in geologically stored carbon dioxide over time * Outline the monitoring techniques employed to ensure the carbon dioxide is safely stored * Appreciate the industrial applications of carbon dioxide capture * Recognize the scale of industry required for transporting and storing carbon dioxide * Describe economic considerations for CCS/CCUS * Outline the economic and environmental opportunities and challenges with using carbon dioxide injection in a range of applications * Explain the challenges of regulatory frameworks and public acceptance in a CCS/CCUS project * Identify potential risks of a CCS/CCUS project * Outline the risk assessment and management process Target Audience This VILT course is ideally suited for a technical audience - geoscientists, petroleum and chemical engineers - as well as for economists, regulators, legal staff and managers wishing to learn more about the details of both the technical, regulatory and socio-economic aspects of carbon capture and storage. Participants should have: * Experience with oil and gas, coal or other energy projects * Basic understanding of the energy industry Course Level * Intermediate Trainer Your first expert course leader spent 18 years in the Petroleum Industry before joining academia, in both technical and managerial roles with Shell, Arco and Vico. He has received numerous awards, including Distinguished Service, Honorary member and Special Commendation awards from the American Association of Petroleum Geologist (AAPG) and was AAPG's International Vice-President and recently chairman of AAPG's House of Delegates (the Associations Parliamentary body). He is an SPE Distinguished Lecturer (DL) and has served as DL for several other professional organisations, including, AAPG, IPA and PESA. He is currently a Professor of Petroleum Geology and Engineering at the Australian School of Petroleum, University of Adelaide. He holds the South Australia State Chair in Carbon Capture & Storage (CCS) and is also presently Distinguished Scientist of the Cooperative Research Centre for Greenhouse Gas Technologies (CO2CRC), having served earlier as the Storage Program Manager and Chief Scientist. Your second expert course leader has a wide and deep knowledge of major capture technologies: solvent, membrane and adsorption based technologies and has developed pathways for retrofitting CO2 capture and storage (CCS) to fossil fuel-based power plants. He has been actively engaged in Post-combustion capture project management and demonstration projects in Victoria's Latrobe Valley on CO2 capture and hydrogen production, and on CO2 capture using membrane contactor technology. He has led various feasibility studies for the Asian Development Bank on CO2 Capture at Indian Oil Corporation's refineries, for JPOWER on hydrogen production from Victorian brown coal and for Kawasaki on incorporation of CCS in hydrogen production from fossil fuel. He has authored multiple peer reviewed journal articles, co-authored various confidential reports on CO2 capture, utilization and hydrogen production and utility, and has presented his work at various conferences, symposiums and seminars. He has a PhD in Chemical Engineering from Monash University Australia and a Master of Technology in Process Engineering from Indian Institute of Technology Delhi India. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information about post training coaching support and fees applicable for this. Accreditions And Affliations

FORS Lo-CITY Driving CPC Course Online

By Total Compliance

#Online Events #OnlineClasses #OnlineBusinessClasses #transport #cpc #drivers #fors #hgv #lgv #drivercpc #online_trainin #driver_training #driver_safety

Gas Turbines, Co-Generation and Combined Cycle Power Plants

By Asia Edge

ABOUT THIS TRAINING COURSE This 5 full-day course will cover all aspects of gas turbines, co-generation and combined cycle power plants. It will cover in detail all the components of these types of power plants such as: compressors, gas and steam turbines, heat recovery steam generators, deaerators, condensers, lubricating systems, instrumentation, control systems, and economics. The design, selection considerations, operation, maintenance, pay-back period, economics of co-generation plants and combined cycles, as well as, emission limits, reliability, monitoring and governing systems are also covered in detail. This course will also provide up-dated information in respect to all the significant improvements that have been made to co-generation and combined cycles power plants, during the last two decades. The course will illustrate through sophisticated computer simulation how gas turbines, co-generation and combined cycle plants perform under steady-state and transient conditions. In addition, the participants will learn how to use the computer simulation program which provides the following benefits: 1. Allow the operator to extend the gas turbine operating period by avoiding unnecessary outages and maintenance activities. 2. Determination of essential gas turbine maintenance activities to reduce the duration of outages. 3. Profit optimization of co-generation and combined cycle plants. 4. Minimization of the environmental emissions of co-generation and combined cycle plants. Training Objectives * Power Plant Computer simulation: Gain a thorough understanding of computer simulation of gas turbines, co-generation, and combined cycle plants. * Power Plant Components and Systems: Learn about all components and subsystems of the various types of power plants such as gas turbines, co-generation and combined cycle plants * Power Plants Economics: Examine the advantages, applications, performance and economics of power plants such as: gas turbines, co-generation, and combined cycle plants * Power Plant Equipment: Learn about various power plant equipment including: compressors, turbines, governing systems, combustors, deaerators, feed water heaters, etc. * Power Plant Maintenance: Learn all the maintenance activities required for power plants such as: gas turbines, co-generation plants and combined cycles to minimize their operating cost and maximize their efficiency, reliability, and longevity * Power Plant Environmental Emissions: Learn about the monitoring and control of environmental emissions. * Power Plant Instrumentation and Control Systems: Learn about the latest instrumentation and control systems of gas turbines, co-generation and combined cycles power plants * Power Plant Reliability and Testing: Increase your knowledge of power plant predictive and preventive maintenance, reliability and testing. * Power Plant Selection and Applications: Gain a detailed understanding of the selection considerations and applications of power plants such as: gas turbines, co-generation and combined-cycle power plants * Power Plant Profitability: Learn about the reliability, life cycle cost, profitability, refurbishment, and life extension methods for gas turbines, co-generation and combined cycle power plants. Target Audience * Engineers of all disciplines * Managers * Technicians * Maintenance personnel * Other technical individuals Course Level * Basic or Foundation Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: * 'POWER GENERATION HANDBOOK' second edition, published by McGraw-Hill in 2012 (800 pages) * Practical manual (500 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; * Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. * Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. * Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. * Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). * Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: * The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 * The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). * The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). * Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Design Of Circulating Fluidized Bed Boilers

By Asia Edge

ABOUT THIS TRAINING COURSE This 5 full-day course will provide a comprehensive understanding of the design of circulating fluidized bed (CFB) boilers. The design of all CFB boiler components and equipment including furnace, cyclones, economizers, superheaters, reheaters, loop seals, expansion joints, refractory, and L-valves will be covered in detail. All potential operating problems and major operating problems, corrective actions and maintenance required for CFB boilers will be covered thoroughly. This course will focus on designing CFB boilers that have the highest efficiency, and maximum longevity and capacity factor. All the common problems encountered in CFB Boilers will be discussed in detail.This includes thermally induced failures, anchor system induced failures, water walls tube failures, NMEJ damages, clinker formation, refractory damages, APH tube chock-up, erosion and corrosion. The solutions to each of these problems will be presented. All repair and refurbishment methods, preventive and predictive maintenance required for CFB boilers will be covered in-depth. Several studies have confirmed that CFB boilers are the best method for power generation.This is due to their fuel flexibility, and lowest electricity cost among all types of boilers. This technology is in great demand due to various other advantages such as lower emissions as compared to other types of boilers and has a carbon footprint well below the norms laid down by the World Bank emission requirements. This course is a MUST for anyone who is involved in the design, operation or maintenance of circulating fluidized bed boilers, because it covers how these boilers are designed and provides guidelines and rules that ensure the CFB boilers have great performance. This course will also provide up-dated information in respect to the design of supercritical once-through CFB boilers and ultra supercritical CFB boilers. Training Objectives * Circulating Fluidized Bed Boiler Design: Gain a thorough understanding of the best design methods of circulating fluidized bed boilers. * Design of Circulating Fluidized Bed Boiler: Components and Systems: Learn all the techniques used to design CFB boiler equipment and systems including furnace, cyclones, economizers, superheaters, reheaters, loop seals, expansion joints, refractory, and L-valves. * Design of Circulating Fluidized Bed Boiler to Achieve Highest Efficiency, and Best Performance and Economics: Gain a thorough understanding of all the methods used to design CFB boilers having the highest efficiency, longevity and capacity factor as well as best economics. * Circulating Fluidized Bed Boiler Equipment: Learn about various equipment of circulating fluidized bed boilers including: furnaces, cyclones, economizers, superheaters, reheaters, ammonia injection systems, electrostatic precipitators, polishing dry scrubbers, fuel and sorbent feeding systems, bottom ash handling and extraction systems and materials. * Circulating Fluidized Bed Boiler Environmental Emissions: Learn about the monitoring and control of environmental emissions from circulating fluidized boilers. * Circulating Fluidized Bed Boiler Instrumentation and Control Systems: Learn about the latest instrumentation and control systems of circulating fluidized bed boilers. * Circulating Fluidized Bed Boiler Reliability and Testing: Increase your knowledge of predictive and preventive maintenance, reliability and testing of circulating fluidized bed boilers. * Circulating Fluidized Bed Boiler Selection and Applications: Gain a detailed understanding of the selection considerations and applications of circulating fluidized bed boilers. * Circulating Fluidized Bed Boiler Maintenance: Learn all the maintenance activities required for circulating fluidized bed boilers, to minimize their operating cost and maximize their efficiency, reliability, and longevity. * Circulating Fluidized Bed Boiler Refurbishment, and Life Extension Methods: Learn about life cycle cost, profitability, refurbishment, and life extension methods for all types of circulating fluidized bed boilers. * Circulating Fluidized Bed Boiler Commissioning: Understand all the commissioning requirements of circulating fluidized bed boilers. * Circulating Fluidized Bed Boiler Codes and Standards: Learn all the codes and standards applicable for circulating fluidized bed boilers. Target Audience * Engineers of all disciplines * Managers * Technicians * Maintenance personnel * Other technical individuals Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: * 'POWER GENERATION HANDBOOK' published by McGraw-Hill in 2012 (800 pages) * Design of Circulating Fluidized Bed Boiler manual (600 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; * Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. * Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. * Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. * Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). * Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: * The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 * The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). * The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). * Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Combustion Engineering for Coal Fired Power Plants

By Asia Edge

ABOUT THIS TRAINING COURSE This 5 full-day course provides detailed description of all combustion equipment and systems used in pulverized coal boilers and circulating fluidized bed (CFB) boilers including pulverized coal burning systems, coal feeder, pulverizer and classifier, pulverized coal burners, furnace and fans. This course provides also a comprehensive explanation of all boiler combustion control systems including pulverizer control system, combustion control, control of coal and air flow into the boiler, furnace pressure control, oxygen trim control, nitrogen oxides (NOx) and sulfur oxides (SOx) control, control of ammonia injection, flue gas dew point control, purge control, flame monitoring and tripping system as well as their tuning methods. All boiler control systems are covered as well in this course including drum level feedwater control, main steam and reheat steam temperature control, boiler limits and runback, sliding or variable pressure control, heat rate optimization with sliding pressure control, boiler-turbine coordinated control, etc. The course provides also detailed explanation of Boiler NFPA 85 Code (Boiler and Combustion Systems Hazards Codes) and American National Standard Institute/Instrument Society of America Code (ANSI/ISA-77-44-01-2007 Code). The burner management systems (BMS) and examples of boiler permissive starting logic and protective tripping logic will be explained thoroughly. The various methods used to calculate the boiler efficiency are covered in detail in this course including the direct and indirect methods. All the factors which affect the efficiency and emissions of pulverized coal boiler and CFB boiler will be explained thoroughly. The course covers also all the methods used to improve the efficiency of pulverized coal boilers and CFB boilers including improvement to their combustion efficiency and control systems performance. Training Objectives * Boiler Combustion Equipment and Systems: Gain an in-depth understanding of all boiler combustion equipment and systems including pulverized coal burning systems, coal feeder, pulverizer and classifier, pulverized coal burners, furnace and fans * Boiler Combustion Control Systems: Gain a thorough understanding of all boiler combustion control systems for pulverized coal boilers, and CFB boilers including pulverizer control system, combustion control, control of coal and air flow into the boiler, furnace pressure control, oxygen trim control, nitrogen oxides (NOx) and sulfur oxides (SOx) control, control of ammonia injection, flue gas dew point control, purge control, flame monitoring and tripping system * Boiler Conventional Control Systems: Gain an in-depth understanding of all boiler conventional control systems including drum level feedwater control, main steam and reheat steam temperature control, boiler limits and runback, sliding or variable pressure control, heat rate optimization with sliding pressure control, and boiler-turbine coordinated control * Boiler NFPA 85 Code (Boiler and Combustion Systems Hazards Codes) and American National Standard Institute/Instrument Society of America Code (ANSI/ISA-77-44-01-2007 Code): Learn about NFPA 85 code and ANSI/ISA-77-44-01-2007 code * Burner Management System and Boiler Permissive Starting Logic and Protective Tripping Logic: Gain an in-depth understanding of burner management system and boiler permissive starting logic and protective tripping logic * Boiler Efficiency Calculations: Learn how to calculate the boiler efficiency using the direct and indirect methods * Factors Affecting the Efficiency and Emissions of Boilers: Understand all the factors which affect the boiler efficiency and emissions * Methods Used to Improve the Efficiency of Boilers: Learn about all the methods used to improve the efficiency of pulverized coal boilers, and CFB boilers including improvement to their combustion efficiency and control systems performance * Boiler Instrument and Piping Diagrams: Gain an in-depth understanding of all boiler instrument and piping diagrams * CFB and Pulverized Coal Boilers Equipment and Systems: Learn about various types of equipment and systems used in CFB and pulverized coal boilers including economizers, steam drum, superheaters, air preheaters, ammonia injection systems, etc. Target Audience * Engineers of all disciplines * Managers * Technicians * Maintenance personnel * Other technical individuals Course Level * Basic or Foundation Training Methods Your specialist course leader relies on a highly interactive training method to enhance the learning process. This method ensures that all participants gain a complete understanding of all topics covered. The training environment is highly stimulating, challenging, and effective because the participants will learn by case studies which will allow them to apply the material taught to their own organization. Each delegate will receive a copy of the following materials written by the instructor: * Excerpt of the relevant chapters from the 'POWER GENERATION HANDBOOK' second edition published by McGraw-Hill in 2012 (800 pages) * Excerpt of the relevant chapters from the 'POWER PLANT EQUIPMENT OPERATION AND MAINTENANCE GUIDE' published by McGraw-Hill in 2012 (800 pages) * COMBUSTION ENGINEERING FOR COAL FIRED POWER PLANTS MANUAL (includes practical information about combustion engineering for coal fired power plants - 550 pages) Trainer Your specialist course leader has more than 32 years of practical engineering experience with Ontario Power Generation (OPG), one of the largest electric utility in North America. He was previously involved in research on power generation equipment with Atomic Energy of Canada Limited at their Chalk River and Whiteshell Nuclear Research Laboratories. While working at OPG, he acted as a Training Manager, Engineering Supervisor, System Responsible Engineer and Design Engineer. During the period of time, he worked as a Field Engineer and Design Engineer, he was responsible for the operation, maintenance, diagnostics, and testing of gas turbines, steam turbines, generators, motors, transformers, inverters, valves, pumps, compressors, instrumentation and control systems. Further, his responsibilities included designing, engineering, diagnosing equipment problems and recommending solutions to repair deficiencies and improve system performance, supervising engineers, setting up preventive maintenance programs, writing Operating and Design Manuals, and commissioning new equipment. Later, he worked as the manager of a section dedicated to providing training for the staff at the power stations. The training provided by him covered in detail the various equipment and systems used in power stations. In addition, he has taught courses and seminars to more than four thousand working engineers and professionals around the world, specifically Europe and North America. He has been consistently ranked as 'Excellent' or 'Very Good' by the delegates who attended his seminars and lectures. He written 5 books for working engineers from which 3 have been published by McGraw-Hill, New York. Below is a list of the books authored by him; * Power Generation Handbook: Gas Turbines, Steam Power Plants, Co-generation, and Combined Cycles, second edition, (800 pages), McGraw-Hill, New York, October 2011. * Electrical Equipment Handbook (600 pages), McGraw-Hill, New York, March 2003. * Power Plant Equipment Operation and Maintenance Guide (800 pages), McGraw-Hill, New York, January 2012. * Industrial Instrumentation and Modern Control Systems (400 pages), Custom Publishing, University of Toronto, University of Toronto Custom Publishing (1999). * Industrial Equipment (600 pages), Custom Publishing, University of Toronto, University of Toronto, University of Toronto Custom Publishing (1999). Furthermore, he has received the following awards: * The first 'Excellence in Teaching' award offered by PowerEdge, Singapore, in December 2016 * The first 'Excellence in Teaching' award offered by the Professional Development Center at University of Toronto (May, 1996). * The 'Excellence in Teaching Award' in April 2007 offered by TUV Akademie (TUV Akademie is one of the largest Professional Development centre in world, it is based in Germany and the United Arab Emirates, and provides engineering training to engineers and managers across Europe and the Middle East). * Awarded graduation 'With Distinction' from Dalhousie University when completed Bachelor of Engineering degree (1983). Lastly, he was awarded his Bachelor of Engineering Degree 'with distinction' from Dalhousie University, Halifax, Nova Scotia, Canada. He also received a Master of Applied Science in Engineering (M.A.Sc.) from the University of Ottawa, Canada. He is also a member of the Association of Professional Engineers in the province of Ontario, Canada. POST TRAINING COACHING SUPPORT (OPTIONAL) To further optimise your learning experience from our courses, we also offer individualized 'One to One' coaching support for 2 hours post training. We can help improve your competence in your chosen area of interest, based on your learning needs and available hours. This is a great opportunity to improve your capability and confidence in a particular area of expertise. It will be delivered over a secure video conference call by one of our senior trainers. They will work with you to create a tailor-made coaching program that will help you achieve your goals faster. Request for further information post training support and fees applicable Accreditions And Affliations

Educators matching "EMIS"

Show all 54Search By Location

- EMIS Courses in London

- EMIS Courses in Birmingham

- EMIS Courses in Glasgow

- EMIS Courses in Liverpool

- EMIS Courses in Bristol

- EMIS Courses in Manchester

- EMIS Courses in Sheffield

- EMIS Courses in Leeds

- EMIS Courses in Edinburgh

- EMIS Courses in Leicester

- EMIS Courses in Coventry

- EMIS Courses in Bradford

- EMIS Courses in Cardiff

- EMIS Courses in Belfast

- EMIS Courses in Nottingham